Wednesday, 15-06-2016

This project is a perfect example for integrated project truly, due to it included variety works, such as: civil works, rehabilitation of main station for MV-SWGR panels, make a full protection against fire, rain & humidity, & installation of a full lighting & air conditions.

Add to that: electrical works, like: dismantle of old panels, & installation of new panels instead of them.

Also, we provided all necessary designs as per standard specifications, & get adoption them by a specialized consultant office.

1) Build a full room (5.8×2.5m), includes: floor & roof concretes, paints & lighting.

2) Build a concrete sidewalk (Includes: Supply the necessary materials).

3) Expand the new room from (5.8×2.5)m to (6.4×3.3)m.

4) Make a concrete base in front of the door of old room, with dimensions (2×2m) × thickness (40cm).

5) Make a concrete layer for the new room floor fully (3.3×6.4m), with thickness (15cm).

6) Drilling of 2 trenches to pass cables of 2 capacitor panel (Includes: supply iron cover).

7) Drilling of a new ground hole (1×1×3m) + fix copper plate (1×2)m×5mm + fix copper bar (10cm×10mm×3m) + laying of copper cable 50mm from the hole to the old room, to achieve 2 Ohm.

8) Optimize of 2 ground holes & connect it with panels.

9) Removal of tiles of old room roof, retrofit & insulation of the roof, & supply & erection new tiles & gutters to dispose the water.

10) Format the room floor & paint it by Epoxy (20×5.8m).

11) Paint a room with size (20×5.8×6m) from inside & outside.

12) Supply & installation of full lighting of the old rooms (Lamps/ Sockets/ Wires/ Pipes).

13) Supply & installation of 5 Air conditioning 2.5 HP (Includes: accesseries & copper pipes).

14) Supply & installation of 3 chasiss for MV panel & capacitor panel.

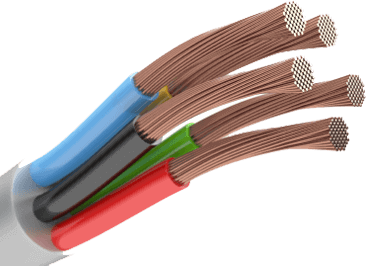

15) Supply & installation of cable terminals (3×240mm).

16) Supply & laying 35m of Aluminum cable (3×240mm).

17) Supply & installation of external sanitation materials.

18) Supply & installation of fire doors & windows.

19) Supply & install iron borders thickness (5×30mm) to protect 4 windows from outside.

20) Supply & install a fan (Toshiba) in the new room & 3 headlamps 1kW (El-Sewedy) over the building.

21) Removal & installation of 18 MV cells & 8 capacitor cells (Includes: remove & install cables).

22) Installation of transformer, batteries, & charger.

■ The following video showing how was the workflow.